Company news

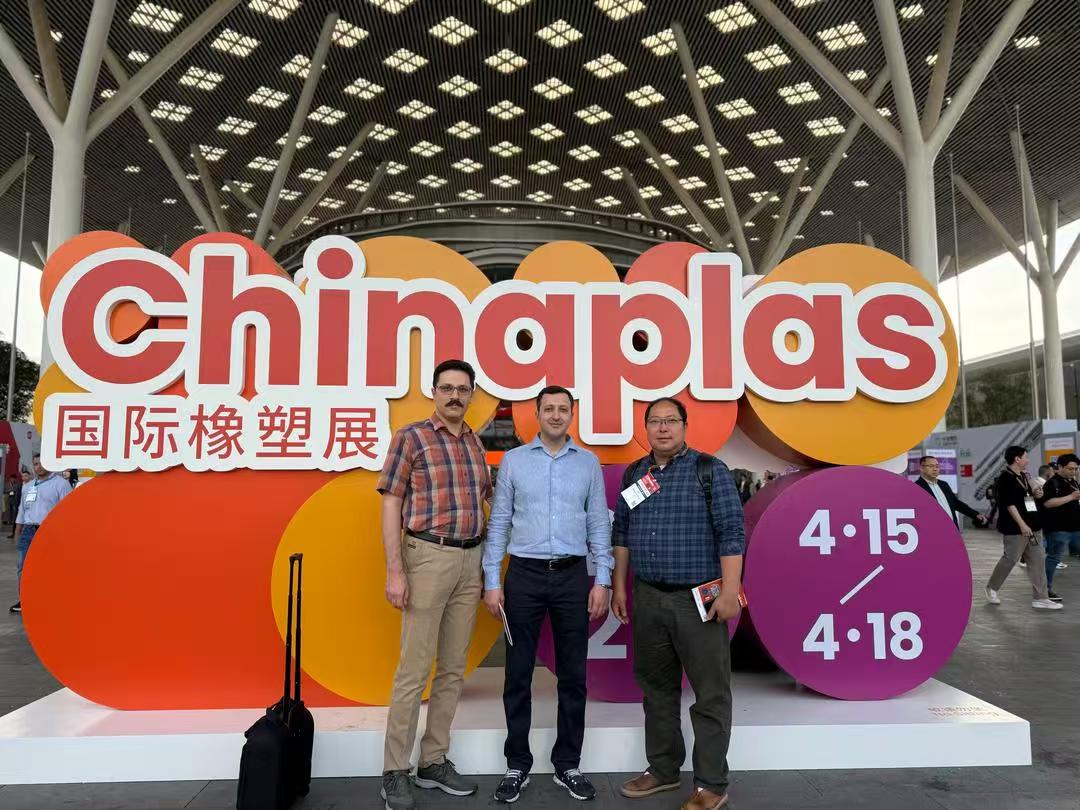

Participate in CHINPLAS 2025 Rubber and Plastic Exhibition

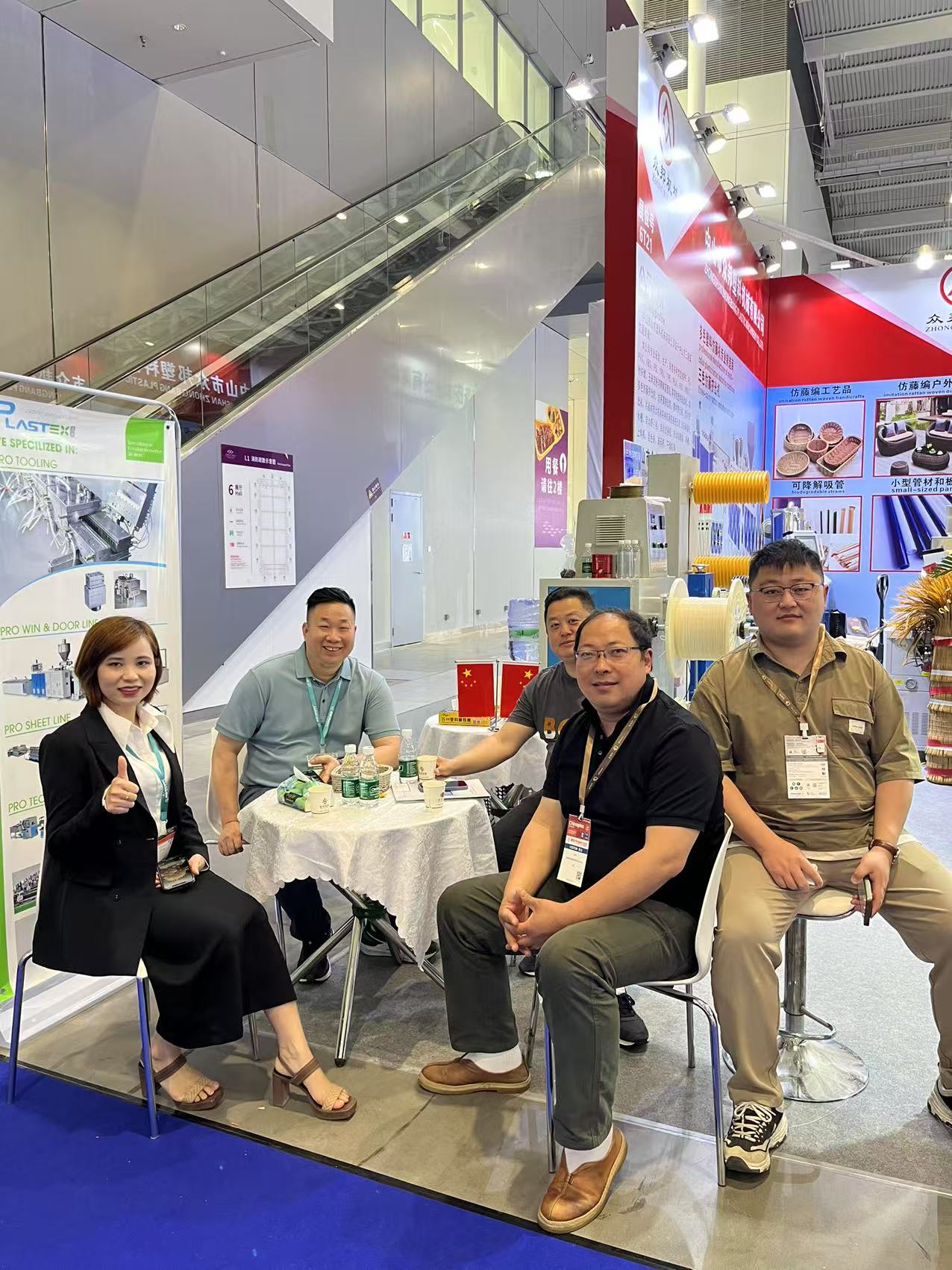

From April 15th to 18th, 2025, Mr. Yuan led a team to participate in the annual China International Rubber and Plastic Exhibition (commonly known as the Yashi Exhibition). This exhibition is the world's largest rubber and plastic industry exhibition. The theme of this exhibition is "Transformation, Collaboration, and Sustainable Shaping Together", bringing together more than 4500 exhibitors, 380000 square meters of exhibition area, and over 280000 visitors from 39 countries, showcasing the cutting-edge technology and future trends of the rubber and plastic industry.

Highlights of this exhibition:

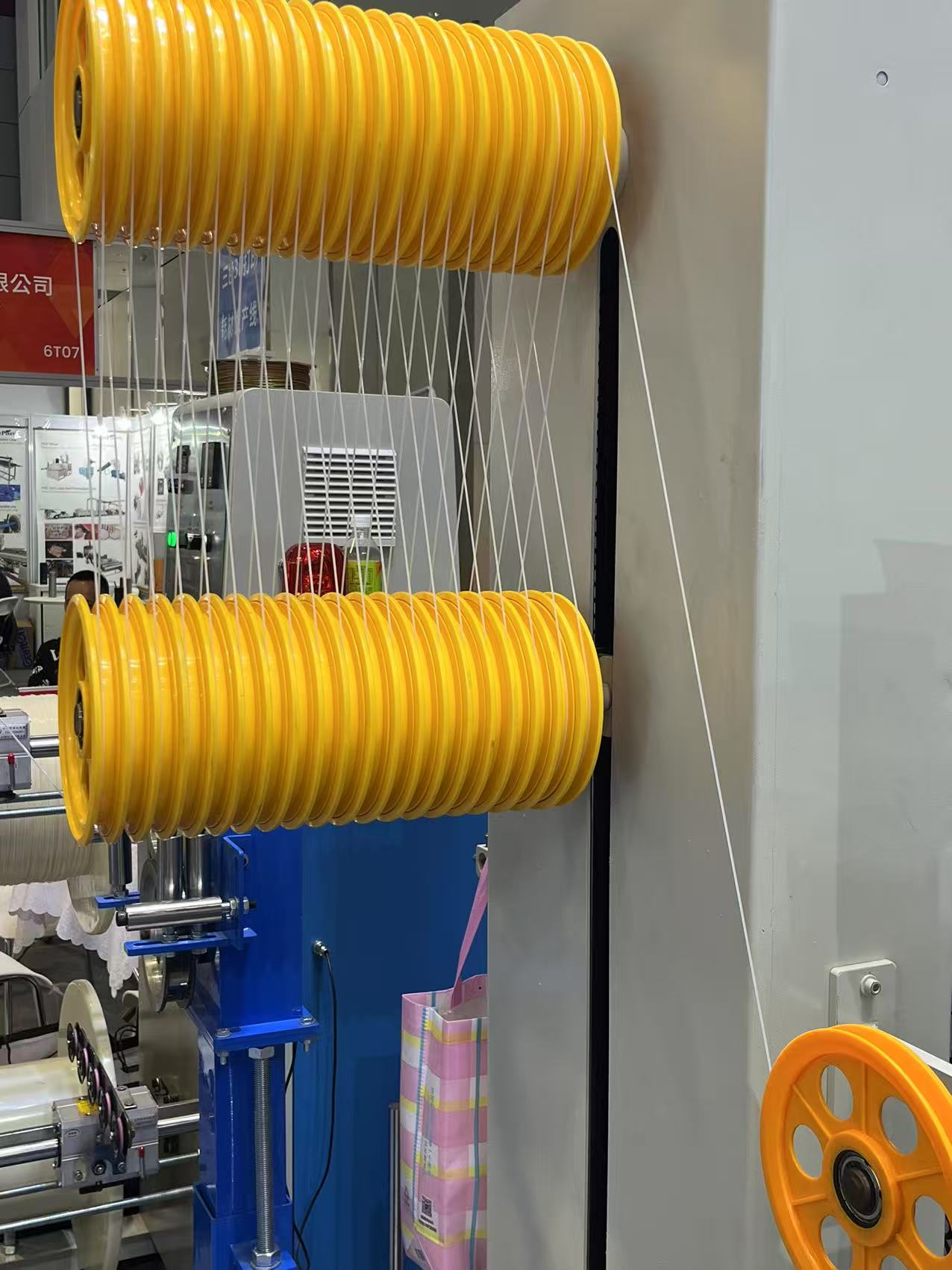

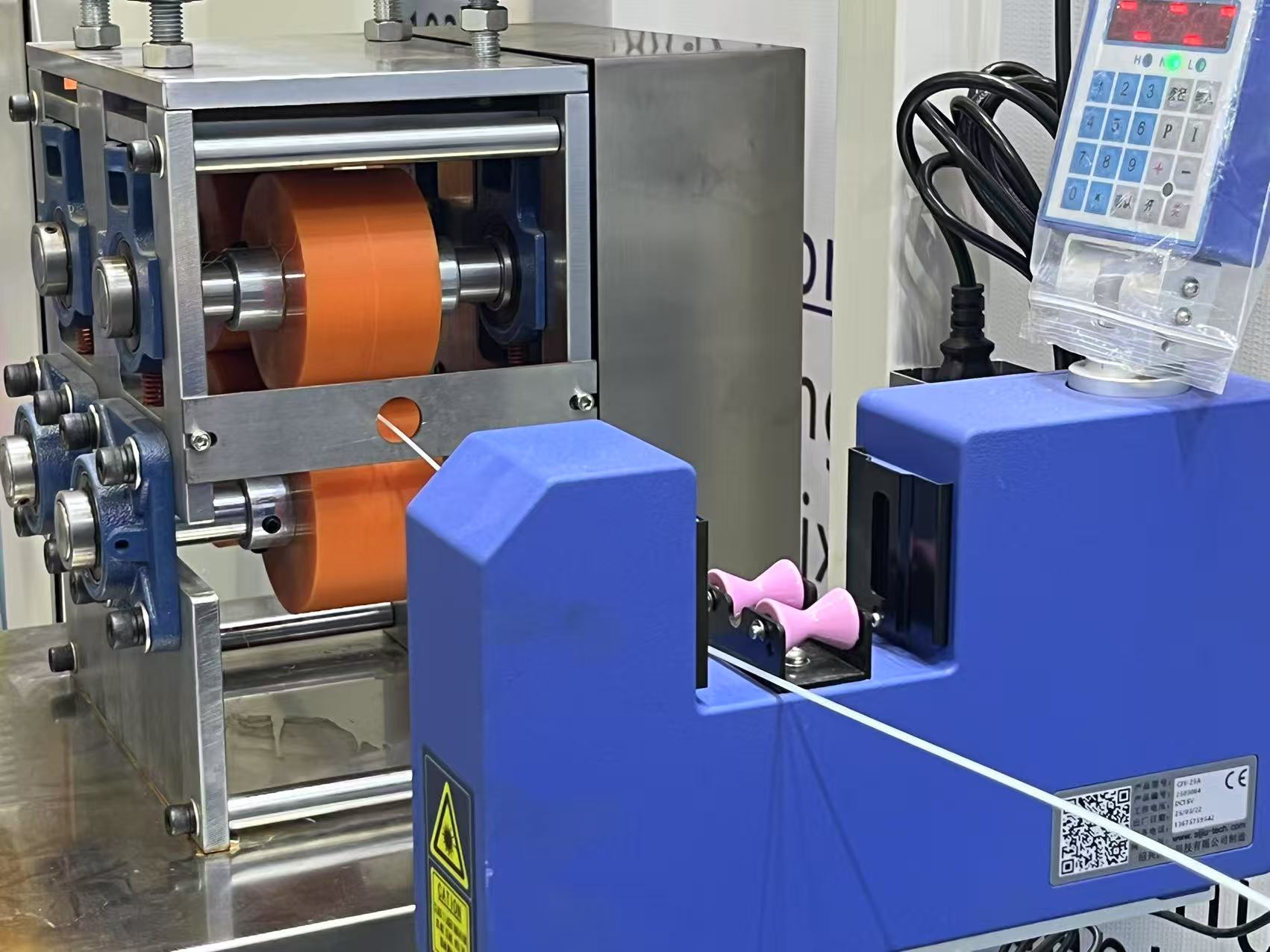

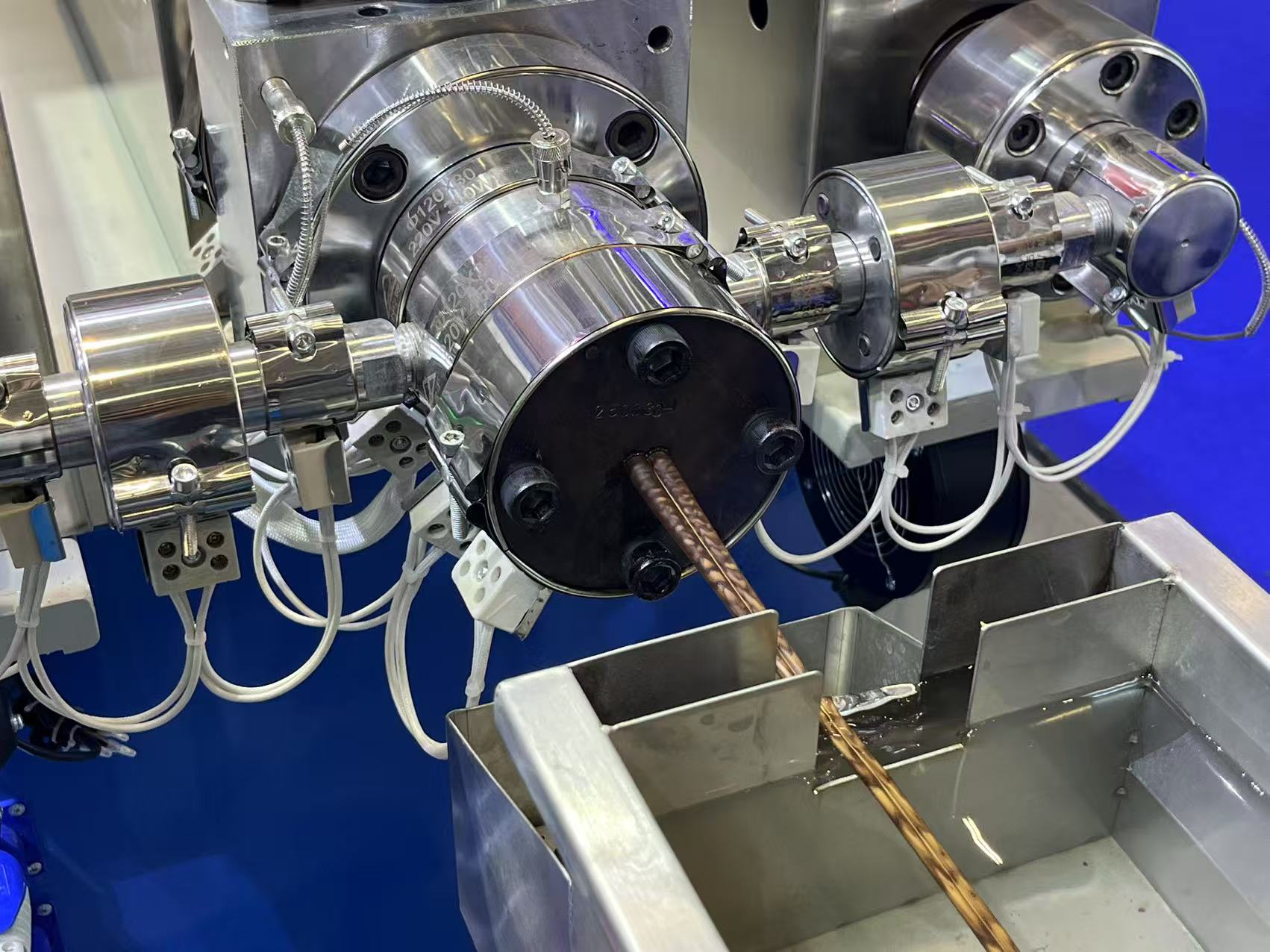

At the Green Materials Revolution exhibition, "sustainability" became the core keyword. Several companies have launched bio based and biodegradable materials, such as Guoke Haina showcasing its "All Natural Degradable Plastic Technology". This technology innovates molecular structures to completely degrade materials into carbon dioxide and water in marine, soil, and other environments, completely eliminating microplastic pollution. Its application scenarios cover fields such as 3D printing materials, plastic packaging, agricultural film, medical sutures, etc., which can be regarded as a milestone breakthrough in environmentally friendly materials. Our company exhibited the latest 3D silk high-speed extrusion production line and conducted on-site demonstrations. The platform was crowded with people and lively. Everyone speaks highly of the 3D silk extrusion technology of PLASTEX. This product will become an important highlight in our company's future development milestones.

The development trend of digitalization and intelligent manufacturing:

Through the exhibition, we also fully understand the development trend of the entire industry and the national trend of "digitalization and intelligent manufacturing". Major exhibitors have put in deep efforts and real skills in the digitization and intelligent manufacturing of their products. Each exhibitor's Eight Immortals crossed the sea, showcasing their unique abilities. The AI intelligence, digital remote control, and PLC+HMI human-machine interaction mode are reflected in various extruders, injection molding machines, and packaging machinery. Our company will continue to explore new ideas and seek new development in this bright spot in the future.

Green transformation has become an industry consensus

The parallel development of high-end and lightweight new energy vehicles, low altitude economy and other fields require higher material performance. For example, carbon fiber composite materials and food grade innovative materials have achieved a balance between lightweight and functionality, becoming the flagship products of many exhibitors.

The synergy between localization and globalization in Chinese enterprises, such as Kingfa Tech's global layout, reflects the competitiveness of Chinese technology in going global.

The circular economy and policy driven "plastic limit orders" and "dual carbon" goals in various countries have accelerated the commercialization process of biodegradable materials. At the exhibition, companies generally use "recyclability" and "low emissions" as product selling points. With the dual promotion of policies and the market, green transformation has become an industry consensus.

Our company's flagship product, the plastic profile extrusion production line, is constantly innovating and timely launching various new WPC production lines and extrusion molds. For example, by utilizing PP/PE recycled materials and combining various plant fibers with different characteristics, the extrusion process of new materials such as outdoor wood plastic flooring, wood plastic fences, and wood plastic wall panels is fully in line with the global trend of plastic limit regulations and dual carbon goals. The large-scale wall extrusion profile mold that I am about to deliver to AB PLAST Group in Sweden is a typical example of promoting the application of recycled PP plastic.

The construction industry is sluggish, and new technologies are emerging

With the downturn of the real estate industry in China's domestic market, our company's original leading product, the extrusion industry of plastic steel door and window profiles, is generally in a slump. The number of people in the plastic steel door and window industry who came to visit this time was significantly reduced, especially the number of traditional businessmen from Türkiye, Germany and the United States. Under the decisive decision of Mr. Yuan, our company timely launched the "explosive" imitation rattan extrusion production line. More brilliant at this exhibition. It can be described as a sudden rise. Obtained impressive results.

The imitation rattan extrusion production line is used to produce plastic rattan strips of various shapes and color textures. The products mainly include round rattan, flat rattan, embossed rattan, simulated rattan, effect rattan, dreamy rattan, color changing rattan, etc. They are widely used in indoor and outdoor furniture, such as tables, chairs, sofas, and various woven crafts. The product has the characteristics of strong extensibility, washability, resistance to mold, UV protection, and resistance to adverse weather and environmental effects.

Our company's rattan machine is widely sold in the Pearl River Delta and Yangtze River Delta regions, forming a domestic customer base mainly in Guangzhou, Zhejiang, Anhui, Hebei, Shandong and other places, as well as a foreign customer base mainly in Vietnam, India, Indonesia, Russia, Iran, and the Middle East. This equipment is designed to meet the continuously improving quality requirements of customers' plastic imitation rattan products. Based on the original imitation rattan extrusion machine series, it has undergone multiple technological innovations and is equipped with high-speed, high extrusion capacity, low melt temperature, and good material plasticizing effect. The dual combination color matching feeding system is used, and the host adopts a digital pneumatic propulsion material changing system, which can make the surface color of rattan change freely.

2025CHINAPLAS has successfully concluded, and # PLASTEX presents a wide range of innovative product combinations around market trends, providing customized solutions for customers in the plastic extrusion industry. At the same time, PLASTEX focuses on multiple hot topics and conducts rich online and offline exchanges and interactions, gathering industry wisdom and discussing material innovation together. Although the exhibition has concluded, the pace of innovation in shaping the future will not stop. Let's return to CHINAPLAS 2025 and take a look at the grand scene together. See you in Shanghai next year!